Making your workflow easier and faster

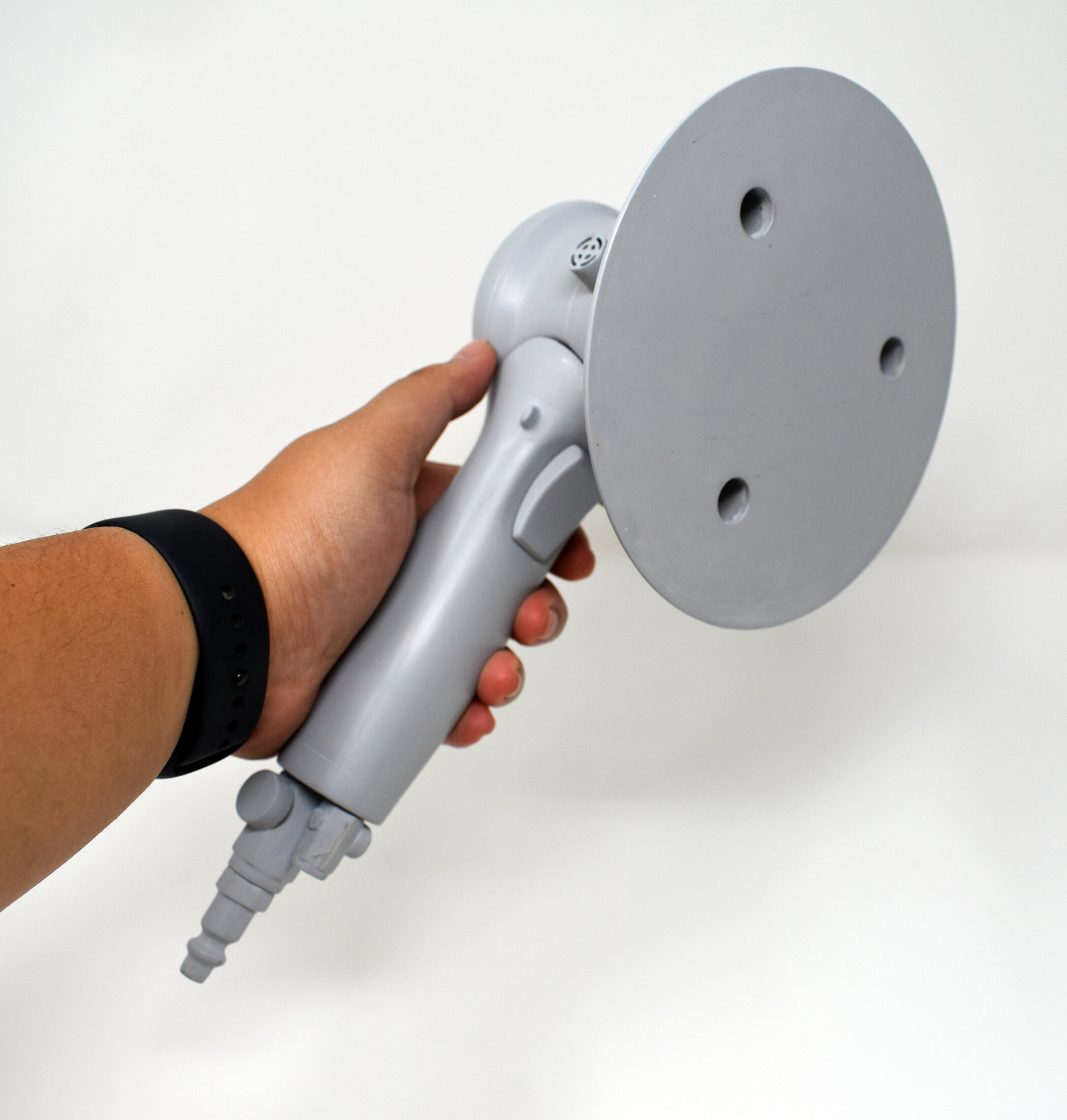

DeWalt Pneumatic Wet Sander

Power-Tool Design

Design Brief

The DeWalt Pneumatic Wet Sander is a power tool designed to combine ergonomics and efficiency for the amateur mechanic.

DIY (Do It Yourself) has increasingly become bigger trend nowadays. People want to learn how to work on things themselves and not rely on expensive professionals. They want the satisfaction and pride of working with their own two hands.

This power tool helps to answer the question, “What if you could combine the actions of two tools into one while maintaining a stress-reducing grip on it?”

Research

While visiting a consumer mechanic, an interview was conducted to observe and record the tools he uses and what he uses those tools for.

This is Jeff Welch. He is an amateur mechanic and industrial designer. He works at the DAAP RPC and is the founder of Modularem Ltd. He and his wife worked to restore a 1978 International Scout (also known as “The International Camp Bus”) 2 years ago. His personal workshop is located in Camp Washington, Cincinnati. He uses a DeWalt polisher/sander for the paint on his car.

“What are some of the things you work on when you bring your car into the shop?”

“Now that it’s restored you kind of wait until something goes wrong. It’s basically like a new car so I’m good for months at a time. Since it was all put back together, things will eventually loosen up.”

“What was the longest part of the restoration process?”

“The polishing process was the longest and most frustrating part.”

Analysis

After the interview and observation, a wet sander/polisher was decided upon because of Jeff’s frustration and time spent using the tool.

The DeWalt brand was also decided upon because it was the brand of the tool that Jeff used and also because of the popularity of the brand along with its reliability and affordability.

A State of the Art Analysis was created looking at the different power tool brands and taking into account the feedback received from Jeff.

In addition, a Brand Analysis over the DeWalt brand looking at features and color scheme.

“What do you look for when buying a new tool"?”

“I look for quality when it comes to tools. I can’t afford the most expensive things, but also the most expensive ones aren’t always the best. I look at refurbished tools as well. Often I can compromise on price because I won’t’ be using the tool a lot.”

“What do you look for in your tools?”

“When looking at tools, I want something simple. Nowadays things are so gaudy and ‘overly masculine.’ A lot of the ‘fancy’ add-ons that don’t affect the functionality of the tool aren’t lasting (coming off/degrading faster).”

Task Analysis

Observed and analyzed a person performing wet-sanding.

Recorded the physical and mental actions taken to perform the task.

Pointed out the pain points or frustration points and areas of trouble when performing the task.

Objectives

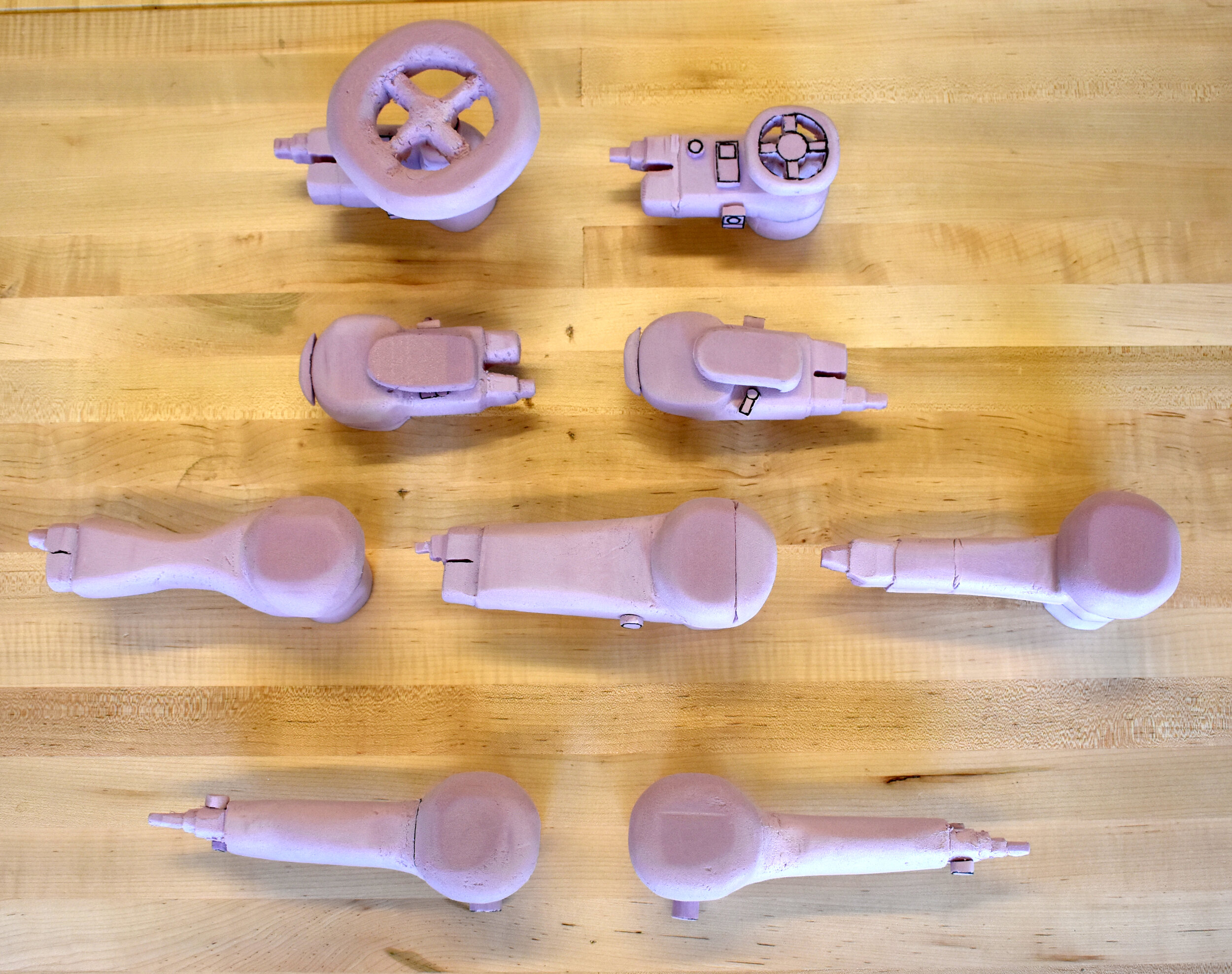

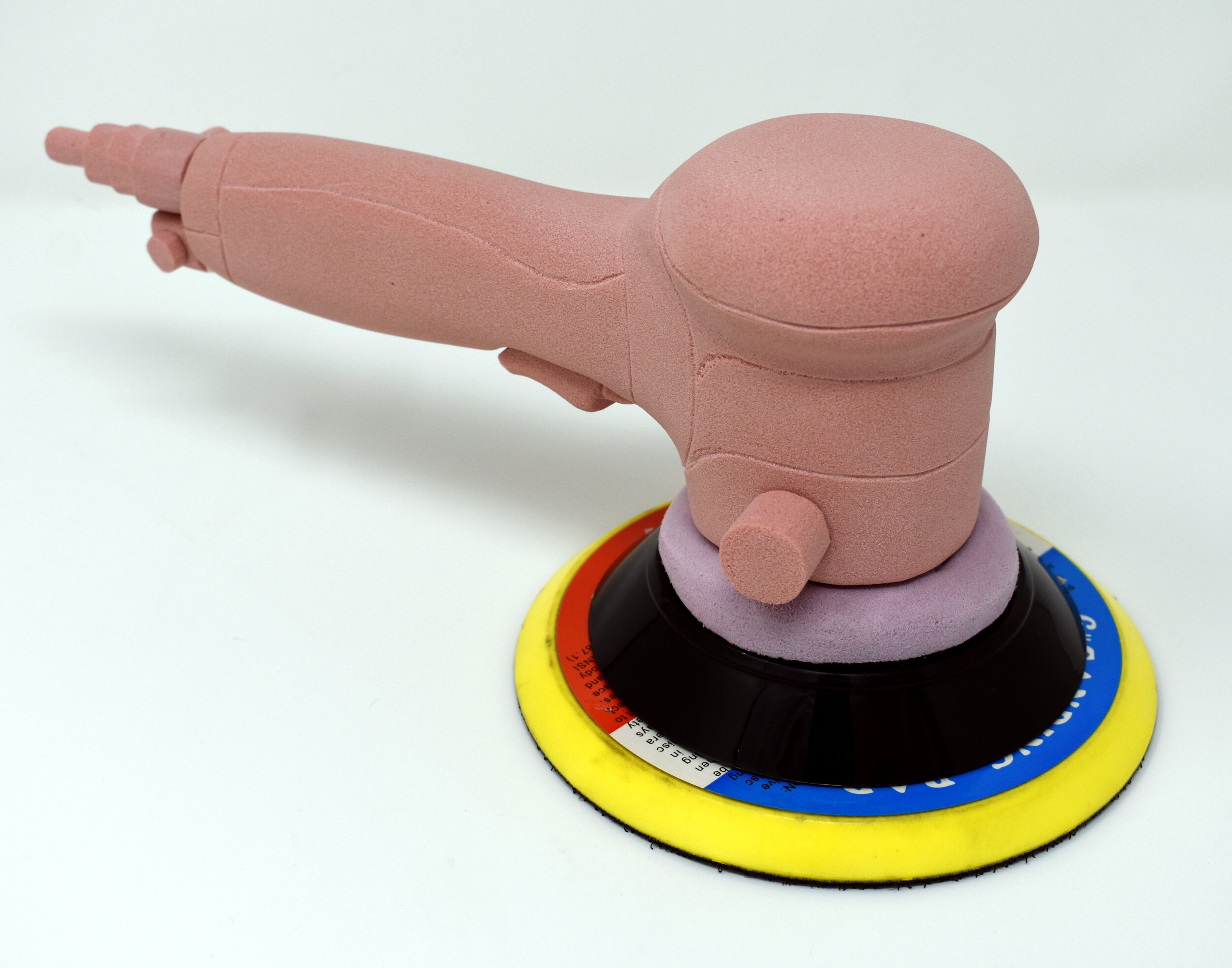

Foam Models

Foam models were made alongside the sketches.

They were made by wire cutting and sanding pink foam to work out proportions, ergonomics, and dimensions.

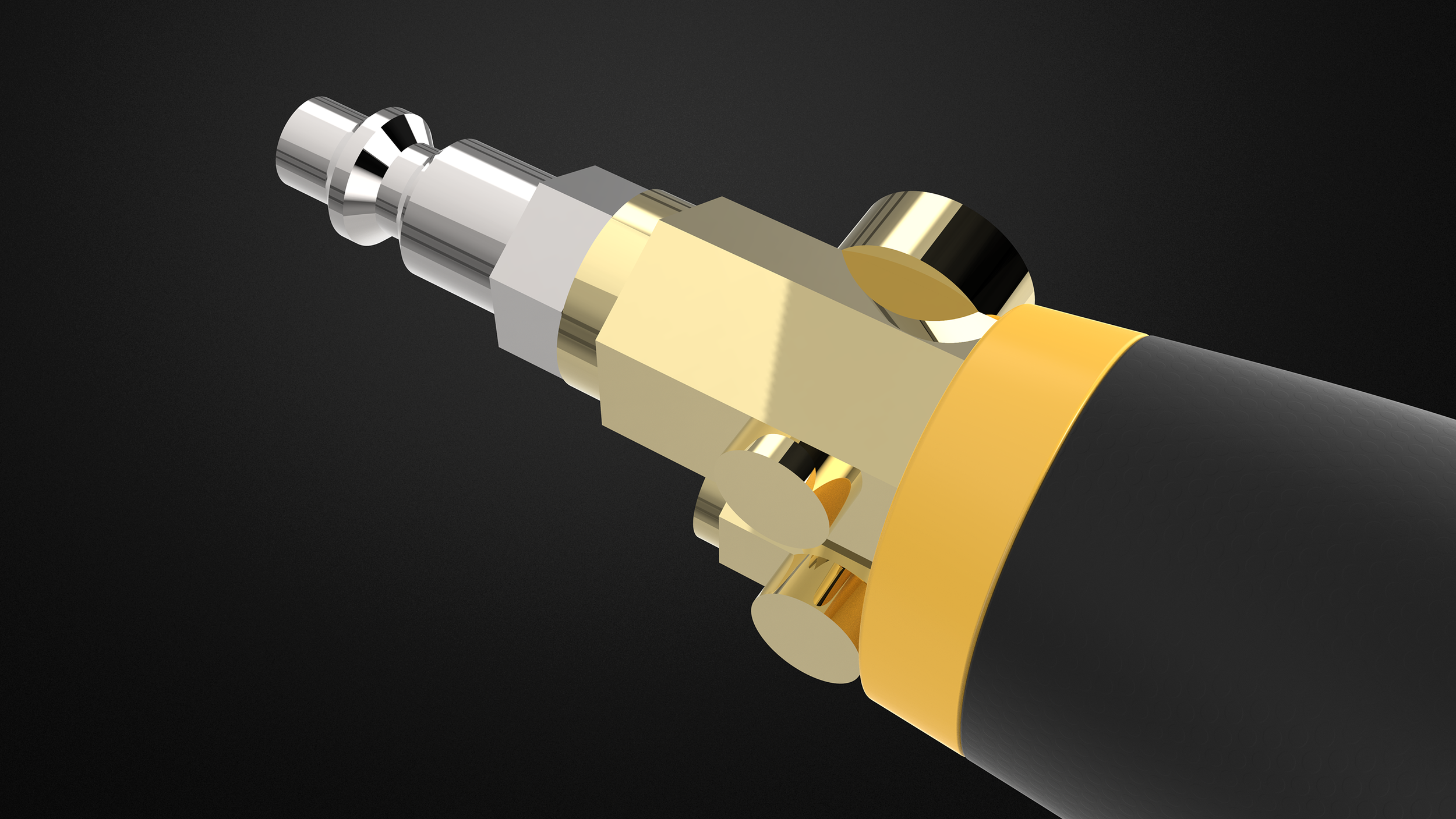

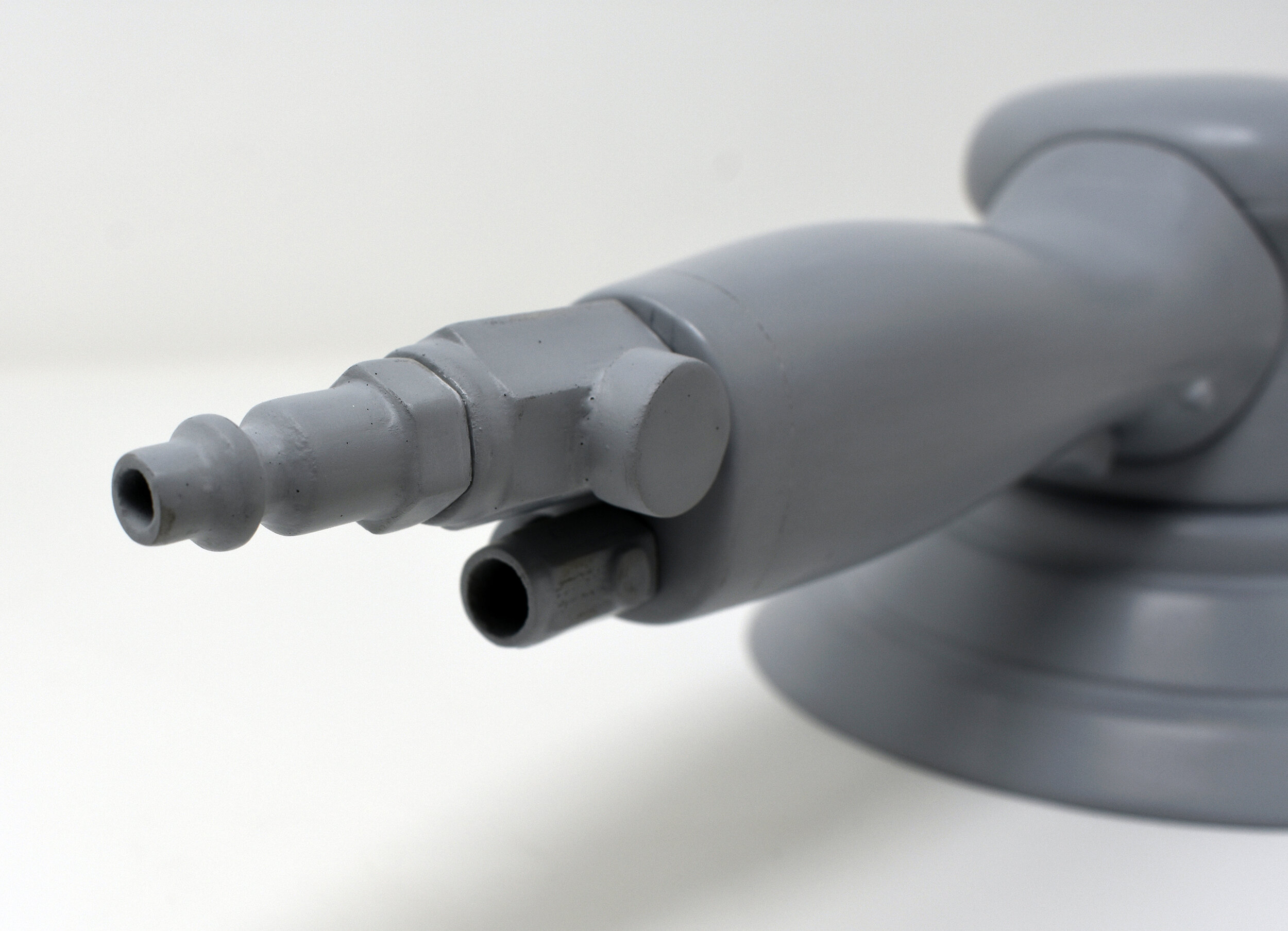

Higher quality models were also made to help narrow down the final design. These were made by rough 3D modeling them in Fusion 360 and CNC milling them out of REN foam.

The final model direction was made by hand cutting and sanding REN foam along with using stock parts from a reverse-engineered pneumatic sander.